For the environment, culture and people

SUSTAINABILITY

Hanamaruki’s Sustainability

- Fulfilling our responsibility as a 100-year-old company toward realizing a sustainable society.

- Since our founding in Nagano Prefecture in 1918, we have contributed to providing healthy and delicious meals to our customers through the fermentation technology we have cultivated over the century. Behind this success lies our ingenuity in coexisting with nature and corporate management based on the philosophy that "People make the company." We will continue to strive for a sustainable society and ensure that the Japanese traditions of miso and Shio Koji are passed on to the next generation.

4 ACTIONS

Four Priority Issues and Initiatives

-

- Safety and Quality

-

- Supporting the Next Generation

-

- Coexisting with Nature

-

- Promoting Diversity

ISSUE01

ISSUE01

- Safety and Quality

- Ensuring Product Safety and Quality

We believe that providing safe and high-quality products to our customers is our mission as a food manufacturer, and we make this our top priority. We have established our own advanced production systems governed by strict quality control standards.

KEY ACTIONS

Our main initiatives

ISSUE02

ISSUE02

- Supporting the Next Generation

- Supporting the healthy growth of the next generation

Miso and Shio Koji are traditional foods born from the wisdom of our ancestors. We are dedicated to passing on these time-honored fermented foods to the next generation while supporting their healthy living and growth.

KEY ACTIONS

Our main initiatives

ISSUE03

ISSUE03

- Coexisting with Nature

- Promoting Environmental Conservation Efforts

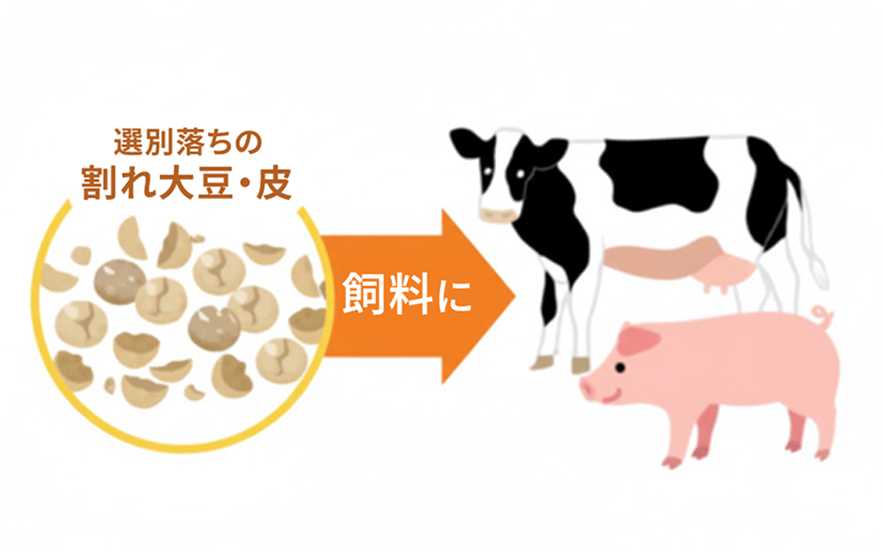

The ingredients of miso are remarkably simple: soybeans, rice, and salt. Through the wonderful wisdom of nature found in fermentation, these ingredients are transformed into the healthy food known as miso. In other words, miso is truly a gift from nature.

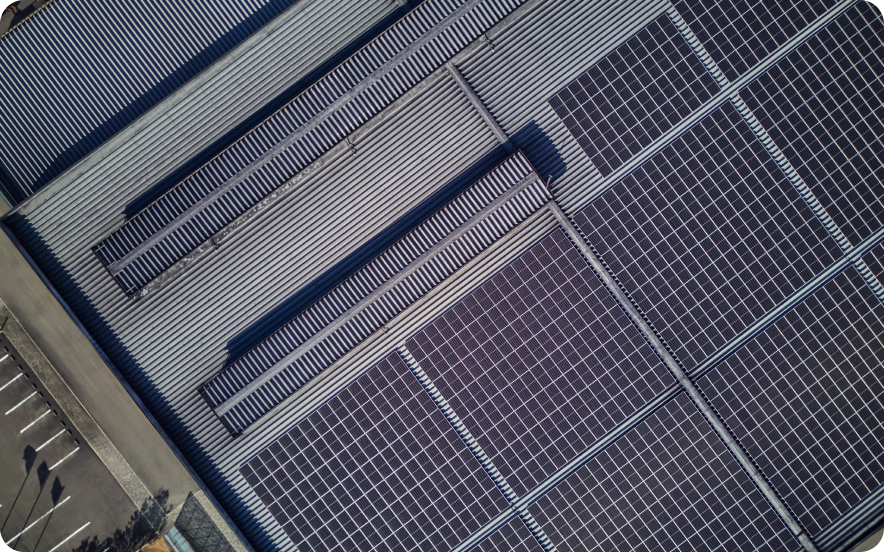

In 2009, we established an Energy Conservation Promotion Committee and have since been working to reduce our company-wide environmental impact. In the years to come, we will continue to promote environmental conservation efforts, always remaining grateful for the blessings of nature.

Promoting environmental vision & environmental management

At Hanamaruki, we aim to utilize traditional techniques and the latest scientific technology to provide delicious, high-quality, and safe products without putting strain on the environment.

●Hanamaruki's Basic Environmental Policy

Living in harmony with the global environment is core mission of Hanamaruki's most important tasks. Recognizing that protecting the global environment is one of the most important issues facing the company, we established an Energy Conservation Promotion Committee in 2009 and are working to reduce the company's overall environmental impact.

●Basic Philosophy

Conserving the global environment is a key theme of the 21st century. Furthermore, the soybeans and rice that are the raw materials for miso can be considered gifts from nature. Therefore, Hanamaruki recognizes the global environment as one of its management resources and is committed to reducing its environmental impact. We strive to continue creating products that are friendly to people and environment.

●Guidelines

- Conduct our business activities in compliance with environmental laws, regulations, and agreements.

- Establish an environmental management system, set environmental objectives and targets, engage in environmental conservation activities, and strive for continuous improvement.

- Give full consideration to environmental impact at all stages of the product and service life cycle..

- Strive to reduce resource usage by promoting resources and energy conservation.

- Work to reduce emissions of greenhouse gases and environmental pollutants, and promote waste reduction, recycling, and container recycling.

- Disclose environmental information to society and promote communication with society.

- Foster environmental awareness among all employees through education and internal initiatives.

●Promotion of Environmental Management

Hanamaruki shares its activity policy with the entire company and promotes environmental management. To reduce our environmental impact, we implement a PDCA (Plan-Do-Check-Act) cycle: setting specific goals, executing initiatives, reviewing results, and establishing the next objectives.

View detail

KEY ACTIONS

Our main initiatives

ISSUE04

ISSUE04

- Diversity of Human Resources

- Creating an environment where diverse talent can thrive

What we value in organizational management is the idea that "People make the company." Looking ahead, we will aim to become a company with a more global perspective, where all employees can work with enthusiasm and without discrimination based on age, gender, race, or any other factor.

KEY ACTIONS

Our main initiatives